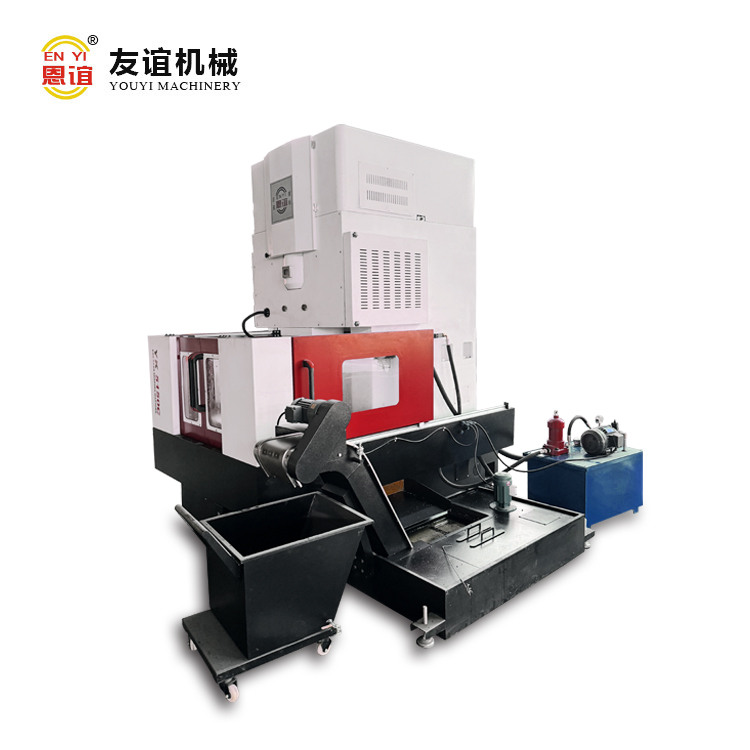

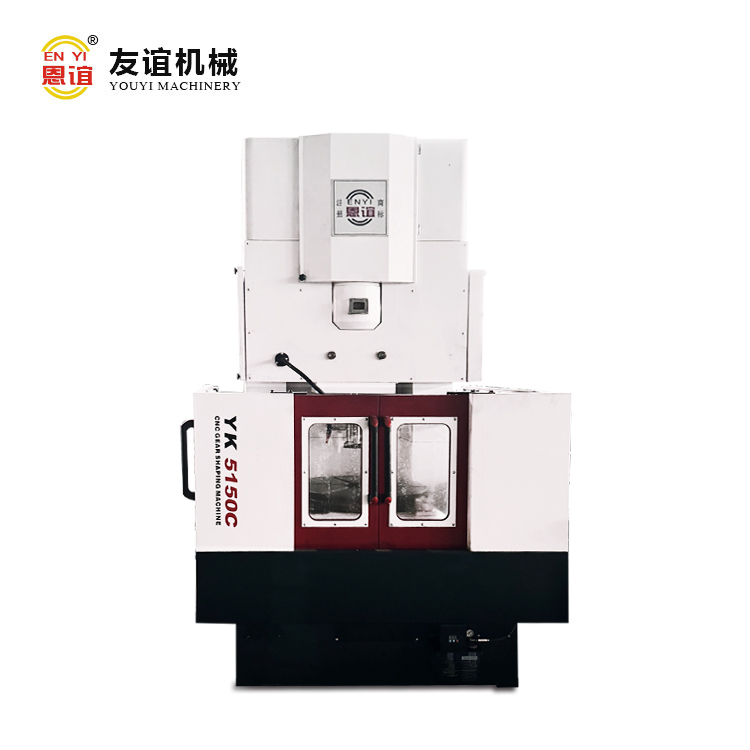

YK5132C CNC gear shaping machine

YK5132C CNC gear shaping machine

- Product ID:YK5132C CNC gear shaping machine

- QQ:88245363

- Phone: 16632950888

- Tel: 13603196487

- Email: 88245363@qq.com

- Time: 2023-11-14 17:27:56

- 留言反馈

Product Features:

The YK5132C CNC gear slotting machine is a four axis three linkage CNC gear slotting machine that and right offset of the column. It implements a longitudinal layout of oblique tool passing. The standard uses the swing of the tool holder to move the tool, the movement of the column for radial feed, and the left configuration of the machine tool adopts the GSK 25IGH CNC system, which controls the x-axis radial feed motion, C1 axis tool rotation motion, and c2 axis workpiece rotation motion. It adopts a variable

frequency speed control motor to achieve stepless speed control of the main motion.

and external gears, and sector gears with a maximum workpiece diameter of 320mm, a maximum modulus This machine tool is used to process cylindrical straight tooth discs, gears, multiple gears, internal of 8mm, and a maximum tooth width of 90mm. Special accessories can also be configured according to user needs to process coupling gears, helical gears, small bevel gears, etc.

Features of this machine tool:

1.The radial feed of this machine tool adopts sliding guide rails, which have good seismic resistance and high guidance accuracy to meet the high-precision repeated positioning requirements. The turbine pairs of the tool rest workbench are all precision grade double pitch worm pairs.

2.Short transmission chain, smooth operation, good rigidity, high productivity, low noise, full functionality, wide adaptability, extremely convenient operation and adjustment, as well as maintenance of machine tools,

3.The machine tool has a stable tool up stop function.

4. By using the mothod of the tool center exceeding the center of the workpiece, double convex wheels are used to adjust the tool, achieving convenient and accurate adjustment of the inner and outer teeth.

5. In order to remedy the inclination of the vertical geometric position of the tool shaft caused by the wear of the tool cam and roller, which exceeds the allowable error of the machine tool, a simple and reliable adjustment mechanism has been designed.

TECHNICAL SPECIFICATIONS

| 项目内容 | description | 技术参数specification |

| 最大工作直径(外齿/内齿) | Max.workpiece dia.extemal/intemal | 320/220+d刀mm |

| 最大模数 | Max module | 8mm |

| 最大行程长度 | Max stroke length | 100mm |

| 最大齿宽 | max tooth width | 90mm |

| 主轴冲程数 | Range of spindle stroke speed | 5-2000Str/min |

| 主轴直径 | spindle diameter | 85mm |

| 刀具中心线至工作台中心线距离 | Centric distance between cutter and worktable | 115-270mm |

| 刀具安装面至工作台面的距离 | Distance from end face of spindle to surface of worktable | 225-335mm |

| 刀具圆周进给量 | Range of alroular foeding | 0-5mm/str |

| 立柱径向进给量 | Range of radial feeding | 0-1600mm/str |

| 工作台面直径 | worktable diameter | 420mm |

| 工作台孔径 | Worktable aperture | 120mm |

| 刀具主轴最高位置径向让刀量 | Cutter spindle back-off at itsupmost position | ≥0.4mm |

机床总功 | Total power consumption | 22kw |

| 机床净重 | Not weight | 8000kg |

| 主机外形尺寸(长“宽*高) | Size(L*W*H) | 3300x1800x2500mm |

CATEGORIES

LATEST NEWS

- Principle of CNC gear hobbing machine processing

- Introduction to domestic manufacturers of CNC gear hobbing machines

- Internal transmission mechanism of CNC gear hobbing machine for electronic gearbox

- The working principle of hobbing machine and hobbing machine

- Conventional safety operation methods for CNC gear hobbing machines

CONTACT US

QQ: 88245363

Phone: 13603196487

Tel: 13603196487

Email: 88245363

Add: Zhengjiazhuang Industrial Cluster, Xingjiawan Town, Renze District, Xingtai City, Hebei Province